You can also be interested in these:

- Is it ok to put cheap thermal paste on your CPU?

- Noctua NH-L9a-AM5: Low profile cooler for Ryzen 7000

- Corsair AF120 RGB Elite full review

- Corsair iCUE H150i ELITE LCD XT full review

Simply put, thermal conductivity is the foundation of the cooling principles on computing technology and ones of the essential techniques for optimal CPUs, GPUs, heatsinks and liquid-based cooling systems operation. It is true that solving the paradigms of heat dissipation in computer science technology nowadays relying in such a mechanic and even archaic means introduces a myriad of possible failing points to the whole equation, making it prone to failure at any time. In this article we will see why thermal conductivity is the key cooling method for PC components and why it continues to be the best.

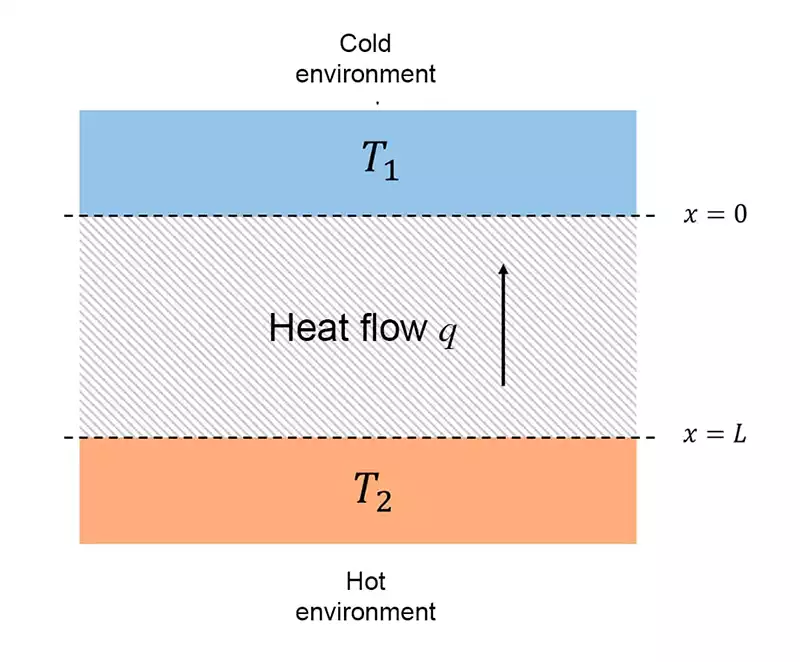

You don’t need to be an astrophysicist to understand the rudiments behind cooling computer components just by subjecting them to close contact. If you have two thermal-conductor materials, where one is cold and the other one is hot, both effects will counteract each other, and this will result in an interaction that will equalize both temperatures at both ends. In between these interactions, there are also additional variables that adds a little more control and stability, like thermal paste and pads.

The thermal conductivity measuring unit is the Watt per meter Kelvin (W/m K), which measures the capacity of an element to transport heat expressed in Joules. This is achieved through surface contact and molecular agitation:

- The heat proceeds through in form of temperature gradient (higher to lower).

- It goes from a high temperature zone with high molecular energy activity.

- Then it shifts to a colder less-energized molecular activity.

This is a constant transfer cycle on which the elements’ temperature is always trying to reach the thermic balance. Therefore, it is always good to have a good transfer speed, because is in our best interest the heat doesn’t build up and propagates at a good rate.

Let’s take, for example, an overclocked CPU. The heat produced by this component would easily slow its performance and in the worst-case scenario, burn the unit down to an irreversible state. Here we need a heavy-duty high-conductive thermic paste.

What does the thermal conductivity of an element depend on?

Cutting to the chase, there are three factors that will determine a good or bad thermal conductivity, and these are: The temperature gradient, the distance between the surfaces and the material properties. However, it is always a good idea to know exactly what are the best conductive materials, for what we put together this small list:

| Material | Thermal conductivity (W/m K) |

| Wood | 0.12-0.04 |

| Glass | 0.8 |

| Concrete | 0.8 |

| Steel | 50.2 |

| Iron | 79.5 |

| Brass | 109 |

| Aluminum | 205 |

| Gold | 314 |

| Copper | 385 |

| Silver | 429 |

| Diamond | 2000-2200 |

| Graphene | 5000 |

Like you might expect, you won’t never see materials like graphene or diamond on any computer component just to dissipate the heat. You will have usually copper or aluminum employed for this purpose. On the opposite side of the scale, there are really bad heat conductors, like the wood or concrete. You will normally these materials in the construction industry, used as insulators.

Does my thermal paste have a high conductivity?

We have a very good idea on what thermal conductivity is. Now, let’s see how all this knowledge get applied in the computing field. CPU thermal paste and thermal pads are created from a compound mix including high-range heat conductive materials applied directly to the Integrated Heat Spreader (IHS) on CPU and other components. This is carried out with the objective of transferring the heat from the source assisted with coolant fluids or fans.

How can I tell if I am using a high quality thermal paste? From all the products on the market the highest amount of heat conductivity is 13 W/m K, which therefore turns out to be a really expensive and scarce product. A thermal paste with 8 W/m K can be considered an above average product. There are 3 types of thermal paste:

- Ceramic: It has a little less conductivity (between 3 and 6 W/m K) and does not conduct electricity. Ceramic thermal paste is not as efficient as the other types and can be easily recognizable by its whitish color.

- Metallic: This thermal paste includes several other conductive metals, plus silicone in the mix, reaching the staggering 13 W/m K.

- Liquid metal: There are no commercial brands offering this product yet, but it promises a record conductivity of 80 W/m K. This material is extremely dangerous and requires to be handled by professionals. The problem with this paste is both heat and electricity conductor and under high temperatures its state changes to a runny liquid that can be extremely harmful when in contact.

We also need to mention the thermal pads, an alternative that has become really popular lately thanks to the ease of its application. It eliminates the need to spread the compound on the IHS, using the right amount of product on each application. Also, among the benefits, the highest conductivity levels achieved with thermal pads is 35 W/m K. An abysmal difference when compared with thermal paste.

This amazing heat conductivity we find on thermal pads is due to the materials used. The graphite, although a little unstable is an amazing conductor, so much so that it was the material used in the nuclear reactors of the Chernobyl plant. Casually, the catastrophe was also the result of a problem related with this material.

Should I be worried about the electric conductivity present on metal based thermal paste?

In a nutshell, all materials used for contact-induced heat conductivity are metal based, which, in all cases contains a minimum of zinc oxide, and therefore a reduced electric conductivity. Although it is good to differentiate a material able to transmit electricity (conductive) from one that’s able to store that electricity as a potential energy (capacitive).

The benefit of capacitive thermal paste over solely conductive is that the first reaches higher conductivity levels, but as a matter of fact, the risk associated with it is higher than this. The difference in conductivity over the less capacitive thermal paste is negligible. You have a higher change to fry your components when not used properly.

More stories like this

- Is it ok to put cheap thermal paste on your CPU?

- Noctua NH-L9a-AM5: Low profile cooler for Ryzen 7000

- Corsair AF120 RGB Elite full review

- Corsair iCUE H150i ELITE LCD XT full review

- Why people prefer water cooling for desktop computers?

- Thermaltake Swafan RGB full review